- PCB Fab

- Etching

- Exposure Machine

- Drilling Machine-Schmoll

- PTH Line

- Solderability Preservative

- Automatic Lamination

- Roll To Roll

- Inner Brown Oxide Line

- CNC Routing Machine

- Laser Direct Imaging

- Immersion Line

- Pre-Treatment

- PCB Assembly

- Automatic Loader

- Screen Printer

- High Speed Chips Mounter

- Multifunction IC Mounter

- Reflow

- Automatic Unloader

- BGA Rework Machine

- Electron Microscope

- Bake Oven

- Oven Temperature Tester

- Components

- Resistance

- Capacitance

- Inductance

- MOS

- MCU/ICS

- DC/DC

- Relays

- Module

- Others

- PCB Design

- AOI

- AOI Inspection

- X-Ray

- X-Ray

- Wave Soldering

- Wave Soldering

- ICT

- ICT

- Anti-Corrosion Paint

- Anti-Corrosion Paint

- Fixture Custom

- Fixture Custom

- LCD Screen Custormization

- LCD Screen Custormization

High Speed Vision Alignment with Ultra-slim Camera

Overall gantry thickness is only 39mm featuring ‘on the fly’ ‘POE’ (Power Over Ethernet) camera; A single CCD split field provides precision simultaneous up-down image acquisition; FOV 9.7 x 6.0 mm.

Advanced Print Head Option

Single axis closed-loop pressure control for dual squeegee eliminates front-to-back variation; a single high precision load cell provides squeegee force, and a unique algorithm calibrates out non-linearity, maintaining the set pressure across the entire board surface.

Ultra-fast, High Efficiency Wiping System

The super-size 65m roll lets you make 10,000 prints between change-outs, for example, with a 5 print frequency, for less down time; the system also features a unique Contamination Control Design.

Innovative EdgeLoc Tooling

EdgeLoc™ uses software-controlled pressure for optimal board holding force, automatically adapts to the programmed board thickness, and firmly holds the board without the use of top clamps for optimum accuracy and repeatability.

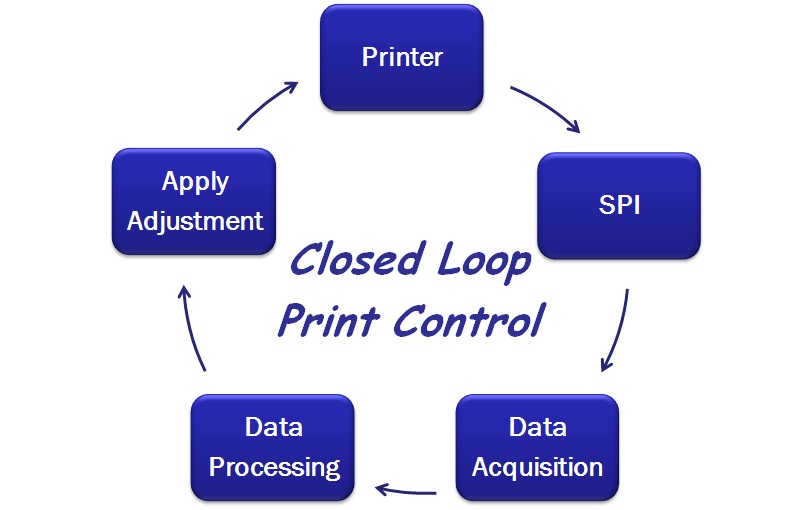

SPI Print Optimizer

The SPI print optimizer communicates with the external Solder Paste Inspection (SPI) system to continuously monitor and auto-correct X, Y, and Theta registration ‘on the fly’ to stay on target and prevent print defects.

Open Apps

Open Apps feature is an open architecture source code which provides customers and third parties the capability of developing custom interfaces in support of Industry 4.0 initiatives and Manufacturing Execution Systems (MES).