- PCB Fab

- Etching

- Exposure Machine

- Drilling Machine-Schmoll

- PTH Line

- Solderability Preservative

- Automatic Lamination

- Roll To Roll

- Inner Brown Oxide Line

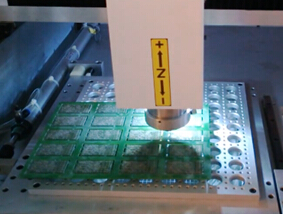

- CNC Routing Machine

- Laser Direct Imaging

- Immersion Line

- Pre-Treatment

- PCB Assembly

- Automatic Loader

- Screen Printer

- High Speed Chips Mounter

- Multifunction IC Mounter

- Reflow

- Automatic Unloader

- BGA Rework Machine

- Electron Microscope

- Bake Oven

- Oven Temperature Tester

- Components

- Resistance

- Capacitance

- Inductance

- MOS

- MCU/ICS

- DC/DC

- Relays

- Module

- Others

- PCB Design

- AOI

- AOI Inspection

- X-Ray

- X-Ray

- Wave Soldering

- Wave Soldering

- ICT

- ICT

- Anti-Corrosion Paint

- Anti-Corrosion Paint

- Fixture Custom

- Fixture Custom

- LCD Screen Custormization

- LCD Screen Custormization

A pcb cnc routing machine is a machine similar to wood router. It uses a router bit to mill the material of the PCB. The hardness of the PCB material wears down the bit, which must be replaced periodically.

Routing requires that single boards are connected using tabs in a panel. The bit mills the whole material of the tab. It produces much dust that has to be vacuumed. It is important for the vacuum system to be ESD-safe. Also the fixturing of the PCB must be tight - usually an aluminium jig or a vacuum holding system is used.

It is very helpful for automotive industrial PCB boards.

The two most important parameters of the routing process are: feed rate and rotational speed. They are chosen according to the bit type and diameter and should remain proportional (i.e. increasing feed rate should be done together with increasing the rotational speed).

|

| Dimensions(W*D*H): | 1220mm*1450mm*1420mm |

| Weight: | 550KG |

| Height offset: | 60~110mm |

| Motor type: | JiaBao series |

| Positioning repeatability: | 0.001mm |

| Axis working area(max): | 680mm*360mm*50mm |

| PCB fixation: | standard、specialization |

| PCB loading/unloading: | manual |

| PCB size (max): | 322mm*322mm |

| PCB thick (max): | 5mm |

| Rigidity fixturing: | standard |

| Fixturing fixation: | machinery |

| Power: | 400W |

| Spindle: | 50000rpm/min |

| Protect: | self/wind cooling |

| Change cutter: | Specialization |

Advantages:

1. Smooth cutting finish only by router cutting .

2. There is little distortion on PCB during cutting because using high-frequency spindle motor . It is 1 / 10 of pressing , 1 / 100 of breaking by hand .

3. One-touch program changeover .

4. Able to cut liner and arc with router machine , diminish the restriction on PCB design .

5. Read QR code or JIG BIT auto select cutting program , or check accordance between cutting program and JIG .

6. Powerful Dust Collection minimized dust adhesion on PCB .

7. High performance router bit that expanded bit life and relief littering .

8. Cut down PCB cost because need not making V-groove on PCB