- PCB Fab

- Etching

- Exposure Machine

- Drilling Machine-Schmoll

- PTH Line

- Solderability Preservative

- Automatic Lamination

- Roll To Roll

- Inner Brown Oxide Line

- CNC Routing Machine

- Laser Direct Imaging

- Immersion Line

- Pre-Treatment

- PCB Assembly

- Automatic Loader

- Screen Printer

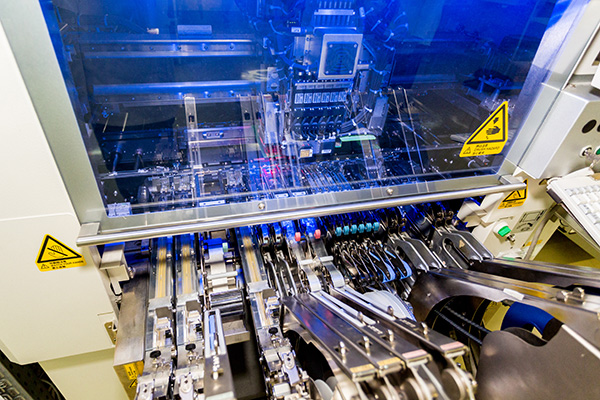

- High Speed Chips Mounter

- Multifunction IC Mounter

- Reflow

- Automatic Unloader

- BGA Rework Machine

- Electron Microscope

- Bake Oven

- Oven Temperature Tester

- Components

- Resistance

- Capacitance

- Inductance

- MOS

- MCU/ICS

- DC/DC

- Relays

- Module

- Others

- PCB Design

- AOI

- AOI Inspection

- X-Ray

- X-Ray

- Wave Soldering

- Wave Soldering

- ICT

- ICT

- Anti-Corrosion Paint

- Anti-Corrosion Paint

- Fixture Custom

- Fixture Custom

- LCD Screen Custormization

- LCD Screen Custormization

There are many SMT equipments on the market, and we choose new type of equipment, because the equipment is an important, and it is directly related to the quality of all aspects of PCBA.

Improved productivity

A faster XY robot and faster tape feeders, as well as a newly developed "flying vision" parts camera, mean increased placing ability for all part sizes and types.

The new H24G high-speed head achieves 37,500 cph (chips per hour) (Productivity priority mode) per module, a 44% improvement from the fastest speed of the NXT II.

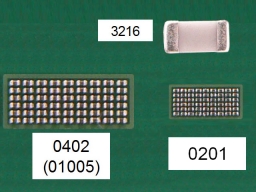

0201 mm part support +/- 0.025 mm placing accuracy

As well as supporting the smallest parts currently being used in mass production (0402 mm, 01005"), the NXT III can also handle the next generation of components heading for the market - 0201 mm parts.

By improving machine rigidity and further refining its independent servo control and vision recognition technology, Fuji has achieved a placing accuracy for small chip parts of +/- 0.025 mm* (3sigma, Cpk≥1.00).

Applicable PCB size (L x W):

M3 III

48 x 48 mm to 250 x 510 mm (double conveyor)*

48 x 48 mm to 250 x 610 mm (single conveyor)

*Double conveyors can handle PCBs up to 280 (W) mm. PCBs larger than 280 (W) mm must be produced by changing the double conveyor to single lane production mode.

M6 III

48 x 48 mm to 534 x 510 mm (double conveyor)*

48 x 48 mm to 534 x 610 mm (single conveyor)

*Double conveyors can handle PCBs up to 280 (W) mm. PCBs larger than 280 (W) mm must be produced by changing the double conveyor to single lane production mode.

Placement accuracy (Fiducial mark standard) :

M3 III

H24G : +/-0.025 mm (Standard mode) / +/-0.038 mm (Productivity priority mode) (3sigma) cpk≥1.00

V12/H12HS : +/-0.038 (+/-0.050) mm (3sigma) cpk≥1.00

H04S/H04SF : +/-0.040 mm (3sigma) cpk≥1.00

H08/H04 : +/-0.050 mm (3sigma) cpk≥1.00

H02/H01/G04 : +/-0.030 mm (3sigma) cpk≥1.00

H02F/G04F : +/-0.025 mm (3sigma) cpk≥1.00

GL : +/-0.100 mm (3sigma) cpk≥1.00

M6 III

H24G : +/-0.025 mm (Standard mode) / +/-0.038 mm (Productivity priority mode) (3sigma) cpk≥1.00

V12/H12HS : +/-0.038 (+/-0.050) mm (3sigma) cpk≥1.00

H08M/H04S/H04SF : +/-0.040 mm (3sigma) cpk≥1.00

H08/H04/OF : +/-0.050 mm (3sigma) cpk≥1.00

H02/H01/G04 : +/-0.030 mm (3sigma) cpk≥1.00

H02F/G04F : +/-0.025 mm (3sigma) cpk≥1.00

GL : +/-0.100 mm (3sigma) cpk≥1.00

Supported parts:

H24G : 0201 to 5 x 5 mm

V12/H12HS : 0402 to 7.5 x 7.5 mm

H08M : 0603 to 45 x 45 mm

H08 : 0402 to 12 x 12 mm

H04 : 1608 to 38 x 38 mm

H04S/H04SF : 1608 to 38 x 38 mm

H02/H02F/H01/0F : 1608 to 74 x 74 mm (32 x 180 mm)

G04/G04F :0402 to 15 x 15 mm

Height : up to 2.0 mm

Height : up to 3.0 mm

Height : up to 13.0 mm

Height : up to 6.5 mm

Height : up to 9.5 mm

Height : up to 6.5 mm

Height : up to 25.4 mm

Height : up to 6.5 mm

lntelligent feeders:

Support for 4, 8, 12, 16, 24, 32, 44, 56, 72, 88, and 104 mm wide tape

Stick feeders:

4 ≤ Part width ≤ 15 mm (6 ≤ Stick width ≤ 18 mm), 15 ≤ Part width ≤ 32 mm (18 ≤ Stick width ≤ 36 mm)

Trays:

Applicable tray size: 135.9 x 322.6 mm (JEDEC standard) (Tray Unit-M),276 x 330 mm (Tray Unit- LT), 143 x 330 mm (Tray Unit-LTC)

Software:

Production using data

Creating program data is very easy with Nexim and production schedules can be created automatically.

Instructions for checking out parts and performing changeover are issued based on these created schedules and part resupply instructions are issued matching the machine operating conditions.

For this, production is performed by connecting the stages with data using Nexim.

Production equipment automatically follows changes in work

By reading the marks and ID on panels in the production line, instructions to perform changeover are issued to machines from Nexim. The machines can perform changeover automatically right up to the positioning of backup pins, which allows production products to be changed without human intervention.

SMT Machines:

ASM brand

JUKE brand

FUJI brand